The arrangement of the personal plot includes many details - from the design of flower beds and flower beds to the selection of small decorative elements. However, perhaps the most important work includes the construction of recreation areas. In this case, the best option would be a wooden gazebo, which not only gives cosiness to the garden, fits well into any landscape design, but also becomes a convenient and spacious place where you can spend time with family and friends. The main plus is the ability to independently erect such a structure. The article will talk about how and from which it is better to do it.

Types of logs for building a gazebo

During the construction of the gazebo, different types of logs can be used. Each of them has not only features, but advantages and disadvantages, which are recommended to be familiarized with before making a final decision.

Did you know? The birthplace of arbors is considered to be Ancient Egypt, and the first mention of them was found in the tombs of the pharaohs.

Rounded (calibrated)

Such logs are pre-cylinderized using a special woodworking machine, i.e. they remove the bark from them and cut off the top layer (carry out calibration). At the exit, the building material acquires a smooth and smooth surface, and also has the same diameter, which can vary from 180 to 320 mm. The lower parts of the logs are also processed - grooves are cut through them, due to which it becomes possible to quickly erect the structure (logs are laid on top of each other). Construction using beams is always popular - log houses have an attractive appearance, which is obtained due to the same shape and size of logs. Also, arbors built in this way are distinguished by high air exchange and good heat retention. Such characteristics make it possible to obtain a comfortable microclimate inside the structure even during cold weather, and also provide a long service life.

Construction using beams is always popular - log houses have an attractive appearance, which is obtained due to the same shape and size of logs. Also, arbors built in this way are distinguished by high air exchange and good heat retention. Such characteristics make it possible to obtain a comfortable microclimate inside the structure even during cold weather, and also provide a long service life.

A gazebo of calibrated logs will require a solid foundation at the base, due to the large weight of the building material. The process itself does not require much effort and time. The most suitable woods are spruce, oak, linden or aspen. The main advantages are the lack of need for both internal and external decoration.

The only treatment that this type of logs will require is a special antiseptic composition that protects the product from the negative effects of moisture, as well as the invasion of insect pests. In addition, calibrated logs are favorably distinguished by moderate cost and availability. There are some disadvantages. Among them is a possible shrinkage of the structure (it may occur several years after the erection), which causes cracks or gaps to appear.

Video: round log

Planed

Planed logs are also often used for the construction of gazebos in the country and in personal plots. Unlike cylindrical ones, the upper layer of wood is removed using an electric planer, as a result of which it is thinner at the output. This approach allows you to get more reliable, warm and protected logs, compared with cylindering, which are characterized by a perfectly smooth surface. Some disadvantages of such a building material are also observed. Kruglyaki does not have a perfect shape and the same size, and therefore, more effort will be required during construction and, accordingly, the costs of fitting logs and ensuring high quality joints. However, despite all efforts, the structure will not differ in symmetry and even walls.

Some disadvantages of such a building material are also observed. Kruglyaki does not have a perfect shape and the same size, and therefore, more effort will be required during construction and, accordingly, the costs of fitting logs and ensuring high quality joints. However, despite all efforts, the structure will not differ in symmetry and even walls.

Did you know? According to Feng Shui teachings, the southwest side of the site would be the optimal location for the gazebo to improve family relationships.

Carriage

Due to the two-sided processing, the carriage is an intermediate version of the timber and log. It allows you to give the structure an even and symmetrical shape, and to give the structure itself a reduced level of thermal conductivity. Reliable logging also ensures a longer operating period and less susceptibility to cracks and gaps, in comparison with cylindrical logs. The minus of the carriage, perhaps, is one - its high cost.

Video: gazebo

Debauched

Barked log houses are often used in the construction of elite and expensive buildings. Such wood is practically not processed, which is why it has a rough appearance, but strength at the maximum level. Due to the uneven and asymmetric surface of the material, the construction will require careful fitting of each log. This feature gives the whole process greater complexity and complexity. However, just such arbors are strikingly distinguished by high reliability and the longest period of operation. The price of the material also differs - the cost of the barked log is much higher in comparison with other species.

This feature gives the whole process greater complexity and complexity. However, just such arbors are strikingly distinguished by high reliability and the longest period of operation. The price of the material also differs - the cost of the barked log is much higher in comparison with other species.

Squeezed

Logs are one of the varieties used for building wood. Initially, the product undergoes a manual type of processing during the removal of the bark using a cycle. This approach allows you to keep all the necessary technical specifications at a high level. The resulting gazebos will last about 100 years, retain heat well and be highly resistant to mechanical damage.

However, the construction process itself is complicated by additional work:

- careful adjustment of logs;

- processing the entire surface from small knots;

- additional fastening.

The disadvantage is the high price category, in which there are scalloped logs.

The disadvantage is the high price category, in which there are scalloped logs.

How to handle a log

Processing of all elements with a special protective solution will help to avoid losing the beautiful appearance of a wooden gazebo. Moreover, each type of logs needs "its" impregnation. For example, for cylinders, a common primer is sufficient, which is able to protect the wood from the development of an undesirable biological environment on it, and a layer of transparent oil is required on top.

Important! Before starting to apply the coating, the logs must first be prepared: thoroughly clean from tar spots, and in case of fungal lesions, additional treatment with copper sulfate will also be required.

If during construction the bars were used, or if there is a thread on the tree, slats - more thorough protection is needed. Chemical reagents can act in this role, which, penetrating deeper, create a strong protective barrier.

In total, there are 3 types of such drugs:

- with preservative composition - acts as a refractory impregnation, while protecting the arbor from the manifestation of mold or fungal formations;

- with compoundsthat are able to lower the level of water absorption of wood;

- with protective compoundproviding a reliable finish (usually use varnishes).

You can also use colored azure impregnations based on alkyds, which can change the color of a wooden structure. For gazebos, which include barbecues, saline solutions that reduce the combustibility of wood will become relevant. For applying impregnation or other chemical reagents, you can use a roller or brush, while the coating thickness should be at least two layers.

You can also use colored azure impregnations based on alkyds, which can change the color of a wooden structure. For gazebos, which include barbecues, saline solutions that reduce the combustibility of wood will become relevant. For applying impregnation or other chemical reagents, you can use a roller or brush, while the coating thickness should be at least two layers.

Important! According to the standards specified in the official fire safety documentation, the distance of the gazebo with barbecue or barbecue from the apartment building should be at least 5 m, and from the fence with neighbors - from 8 m.

Step-by-step construction process

Before starting construction, several preparatory steps should be made:

- Choose design. There are two types of arbors - open and closed. In the first case, the structure is a traditional summer version, consisting of supporting pillars overlapped along the perimeter by a low parapet. It also implies a roof that can protect against precipitation (due to the ease of construction, single or double gable, multi-tongue or hip are acceptable). Closed gazebos have the same design, which, however, is complemented by blind or glazed walls (with pre-defined openings for windows and doors). Inside such buildings, in addition to additional elements (meaning barbecue, stove, etc.), communication systems can be carried out, for example, water, sewage, electricity.

- Decide on the dimensions. Such an indicator of construction, as the size, should primarily be based on the area of the plot, the main functionality of the gazebo, as well as the needs of the owners. Typically, small mobile buildings are characterized by a construction of 1 × 2 m, standard - 3 × 3 or 3 × 4 m. When calculating, it should be noted that a comfortable rest at the table will require about 2 m² per person. If the installation of sun loungers or a sofa is provided, this size increases to 4 m².

- Choose a form. It is assumed that the wooden arbor can have any shape, but the most common are square or rectangular structures. At the same time, open buildings are often made multifaceted, which gives them special grace, and closed winter ones are two-story (the second floor is used as an open veranda). Combined arbors with an attached open canopy gained great popularity.

- Pick a place. The site for the gazebo needs to be selected based on its size. For example, a massive structure is best placed behind the house, not far from the fence. A medium-sized structure can be installed anywhere, but better near large trees that provide additional shading from the sun. When placing portable arbors, the main thing is that they do not block the entrance to the house.

Drawing, tools and materials

Starting to design the structure, you can either:

- go online and find options for free drawings, specifications and calculations;

- to get a ready arbor ("on a turn-key basis");

- order a prefabricated structure and carry out the installation yourself;

- carry out the planning yourself.

Having chosen the last option, the project can be completed based on the following algorithm:

- The first step is to draw a plan of the site on which the place of future construction is marked. When choosing the location of the entrance to the gazebo, it is better to stay on the leeward side.

- Next, a diagram of the future structure is applied.

- After that, load-bearing walls or poles are determined. Taking into account this information, as well as the relief of the site (for example, the presence of differences or bogs), select the type of foundation.

- The main dimensions and the required materials are determined.

- Choose the necessary rafter system and the type of roofing material. Usually they stop on a two-, four-pitched roof with tiles.

When choosing material for the independent manufacture of gazebos, more often choose pine beams or logs as the main building material. Of the tools you may need a hammer, drill, screwdriver, planer, electric saw, electric jigsaw, tape measure, level, screws, chisel and ax.

Important! If the farm does not have any electrical equipment necessary for construction, it can be rented.

Foundation selection

Depending on the type of structure and its dimensions, a different foundation may be required. Usually, for light open arbors, a shallow reinforcement is sufficient, whereas for covered arbors made of logs, a more solid foundation is needed. This is due to the large weight of the structure and high bearing loads.

Monolithic

The creation of this type of foundation requires time and labor, as well as large cash costs, and therefore its construction must be justified. For example, it is planned to erect a massive structure with a fireplace and barbecue inside or take into account the peculiarity of the soil of a particular area (the soil can quickly freeze or sag).

In order to make a monolithic foundation, you will need:

- Mark the plot.

- Dig a pit whose depth should not exceed 50 cm.

- Create formwork around the perimeter of the pit using pieces of wood.

- Lay a pillow on the bottom (sand and gravel, 15 cm each layer). It is she who can prevent the deformation of the base.

- Lay a ruberoid on top (fix the ends inside the formwork) and pour crushed stone with a layer of 5 cm.

- Assemble the frame from the reinforcement, the diameter of which should not exceed 10 mm. In the end, we get a grid with a mesh size of 20 × 20 cm.

- Pour concrete or mortar based on cement and sand into the pit.

In this case, it is worth paying special attention to the height of the slab - it should be no less than 40 cm above ground level.

Tape

The best option for areas with dry sandy soil. The strip foundation is characterized by a complicated design and the need to invest money, time and effort. However, its strength level is more than enough for structures made of brick or wood, the dimensions of which start from 4 × 6 m.

The bookmarking process includes several basic steps:

- First of all, they dig a trench, the depth of which should be at least 50 cm.

- A timber formwork is being erected around its perimeter.

- Crushed stone is poured inside the formwork, with a layer of about 5 cm. After this, they begin to mount the frame from the reinforcement.

- Concrete is poured over the reinforcement.

The period that will be required for complete solidification can be 14-30 days, after which construction can continue (for example, masonry walls).

Columnar

The column foundation has the simplest construction technology, for which it has received wide popularity among summer residents. This design is suitable for clay soil, as well as for wetlands and quicksand. Pillars installed along the perimeter of the gazebo and recessed into the ground (the distance between them and the depth depend on the area of the structure and the type of soil) are used as reinforcement.

Material for them are:

- wooden logs - can be used for open arbors or other light constructions;

- concrete blocks - able to become the basis for a brick structure or a closed garden house;

- asbestos cement pipes - act as a strengthening of frame structures, must be installed in level and poured with cement;

- brick - refers to universal materials that are applicable to any type of structure;

- metal pipes - must be pre-treated with a corrosion inhibitor, do not require cement pouring.

Bottom harness

The next step after laying the foundation is the lower harness (fixing the bottom layer of logs). The best option would be a bar, size 100 × 100 mm. The fastening method used is “half-tree”, due to cutting corners. It has the appearance of a transverse cut on half the thickness of the log (this was the name). Before starting the assembly, it is recommended that you drill holes to install a dowel or key at each corner connection point.

Laying and fixing

The design of the log house involves vertical single-layer stacking of logs in height. The secret of their balance lies in the connection method - in order to ensure it, in each log, at the mating point of the round surface, a special recess is preliminarily formed, the thickness of which should be approximately 1/5 of the diameter of the beam.Such a "bowl" allows you to tightly fix the logs to each other.

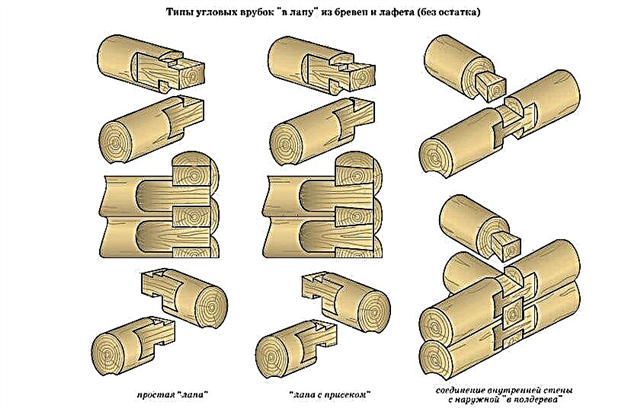

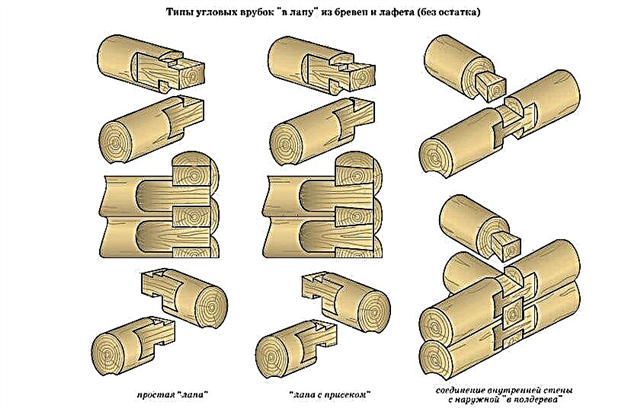

There are two classic ways of joining wood:

- "In the paw" - allows you to significantly save material, but is labor intensive. In the process of preparation, the ends are machined for connectivity. Such a notch enables rigid attachment and eliminates the movement of logs. The ends are given the shape of an irregular quadrangle - the height of the face directed inward to the wall is 6 cm greater than the outer (accordingly, the thickness has the same dimensions).

- "In the bowl" - the process is simple and consists of making a round recess for the transverse log. At the same time, the distance from the edge to the bowl is about 1.5 log diameter. Laying is carried out alternately from each wall. As a result, the outer corners acquire a cruciform shape, due to the protruding parts of the wood.

Roof and floor

The main technical characteristics of the roof should be lightness, rigidity and strength, which should be evaluated taking into account the effects of wind and rainfall. At the same time, the roof supporting system has the same elements in its construction as in conventional construction.

Among them:

- Mauerlat - Acts as an extreme lower support for rafters;

- rafters - a system including inclined rafter legs, vertical racks and inclined struts;

- ridge run - represents a horizontally located beam on which the upper part of the roof rests;

- gable (if available) - is the completion of the facade of the roof and is a series of logs laid out pyramidal.

Additionally, depending on the design, it may be necessary to crate the roof of the arbor. As for the roofing, it is selected based on the planned design. The optimal is considered a wooden floor with a preliminary waterproofing. But metal or soft tiles, decking or ondulin can also be used.

Additionally, depending on the design, it may be necessary to crate the roof of the arbor. As for the roofing, it is selected based on the planned design. The optimal is considered a wooden floor with a preliminary waterproofing. But metal or soft tiles, decking or ondulin can also be used.

As a flooring, a standard scheme using lags is often used:

- on the lower harness fasten logs with metal corners;

- boards with small gaps are laid on top (to release moisture).

Arrangement and interior decoration of the gazebo

Interior decoration is optional (in the absence of thermal insulation) and can be done if the owner wishes. When choosing a material, the main characteristic is its moisture resistance.

The most popular of them include:

- Plastic panels - differs in simplicity and speed of finishing. Of the minuses - its main purpose is purely decorative. Such a coating will not be able to protect from moisture or from the cold.

- Facing stone - reliable and durable material that is highly resistant to stress. However, its laying presupposes the presence of certain skills in such works.

- Wood boards - The best option, which is how easy it is to finish, and reduce material costs.

After all the construction and interior finishing work is completed, the most pleasant time comes - the arrangement of the interior. Here everyone can realize their creative potential, however, it is recommended to adhere to the "golden mean" and not to get out of the general style. First of all, you need to worry about suitable furniture, which should be lightweight and resistant to moisture.

After all the construction and interior finishing work is completed, the most pleasant time comes - the arrangement of the interior. Here everyone can realize their creative potential, however, it is recommended to adhere to the "golden mean" and not to get out of the general style. First of all, you need to worry about suitable furniture, which should be lightweight and resistant to moisture.

Next, install several light sources (for example, a large lamp inside the gazebo and several small light bulbs at the entrance). It will not be superfluous to worry about the small details of the interior, because it is they that give comfort to any room. These include pillows, curtains, tablecloths and more. If the grill is located in the arbor, you need to worry in advance about the presence of a smoke collector, which will eliminate the formation of severe smoke and protect the grill from soot, extending its life.

For the same purpose, it is coated with acrylic varnish. Arbours from a tree are highly appreciated, and it is quite justified. After all, such structures are of high quality and low associated costs. An additional advantage is the possibility of self-construction. The appearance of the gazebo is able to organically fit into any landscape design of the garden, and rest in such a place is distinguished by a special atmosphere of comfort.