Cottage is not only a place where people grow vegetables, here you can also have a wonderful rest. A gazebo is an integral part of landscape design for a summer cottage, which is not only an element of decor, but also functionally necessary. Inside are a table and chairs, sometimes - small benches. Here the family can relax after work on the site or receive guests. In order to make the table comfortable and beautifully looking, it is necessary to adhere to some rules in conducting measurements, choosing materials and working with them.

Types of tables for the gazebo

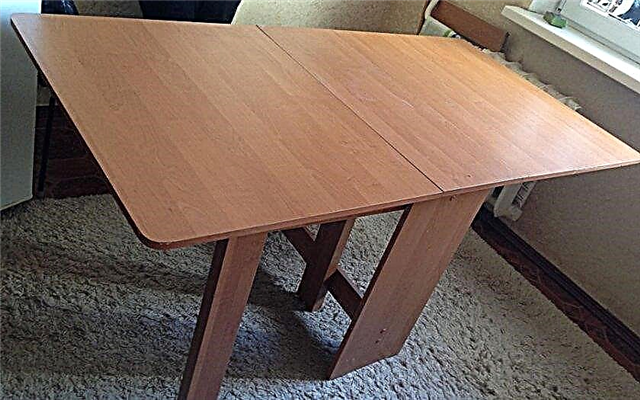

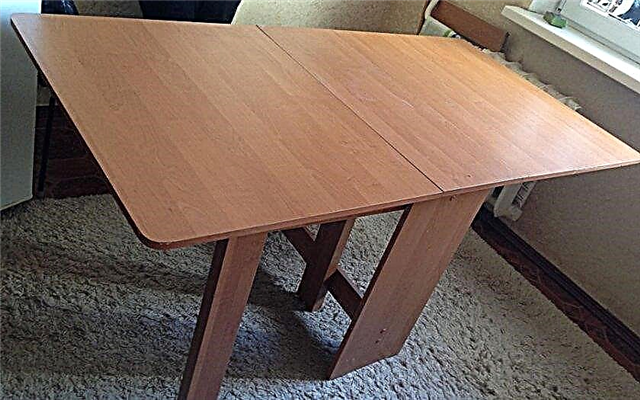

Depending on the type of space presented to the owner, different materials and shapes of the finished product can be selected. The table can be round, square, rectangular and even hexagonal. The choice of form directly depends on the size of the arbor, the number of family members who will rest at it, and of course, on the desire of the owner of the dacha. The hexagonal table of all presented is the most compact. Such a tabletop is able to accommodate six people, which is quite enough for an average family, and also takes up a minimum of space.

Did you know? The most expensive wood for furniture is bokoté. Cost per board foot (0.00236 m³) is $ 33,000.

A rectangular table is the most common, as it can be installed along, adjoining one of the walls of the gazebo. In this way, an acceptable passage will remain and a large number of guests can be accommodated. A square table is best used in small arbors that are designed to relax after work, as an element of landscape design. Round and oval tables are best placed on large areas, as such furniture is designed for a large number of guests.

In addition, you can choose a table based on the material that will be taken as a basis:

- The cheapest and most common option for a gazebo is chipboard table. However, if you make it from this inexpensive material, it will be fragile and quickly lose its presentable appearance.

- Can use fiberboard. A wooden table made of such material will come out moisture-proof and resistant to various physical influences such as shocks.

- From the trunk of a plant. Wood in the modern world is an expensive resource, which means such tables are expensive, therefore, before purchasing this material, it should be borne in mind that moisture will get on it, and, as a result, the tree will deteriorate.

- Glass tables suitable for residential buildings and not practical as furniture in summer houses. Products are easy to damage, but such interior items visually expand the space. If you do not plan to put iron buckets and other bulky objects on it, then it is quite possible to use such unusual material.

- Metal is another material from which you can make a countertop for the gazebo. Such a piece of furniture will be the most durable and wear-resistant, but it will not look so attractive. This option is best chosen when the gazebo has metal elements in its design solution, or, for example, for forged construction.

Drawing and table sizes

In order to make the table perfect both in quality and in appearance, it is necessary to pay special attention to measurements and creating a drawing. Initially, you need to measure the length and width of the gazebo, and then choose the optimal size of the countertop. It is important that there is room for chairs and guests around it.

Did you know? The largest and heaviest tree in the world is General Sherman (California). The trunk volume is about 1500 m³, height - 84 m.

Necessary materials and tools

To make a piece of wood furniture you will need:

- dry timber, the dimensions of which will correspond to the desired size of the product;

- self-tapping screws;

- a grinder with a grinding wheel;

- screwdriver;

- saw or jigsaw.

Step-by-step instructions for creating a wooden table

The whole process of manufacturing an interior item can be divided into several stages, each of which has its own characteristic features. Preparation of materials is the first and one of the most important steps in the entire technological process.

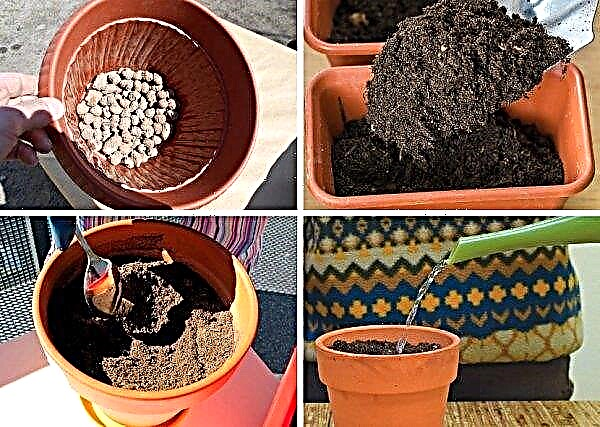

Material processing

At the stage of processing the material, it is necessary to cut the boards, based on measurements that were carried out earlier. Already prepared, they should be left in the sun so that they dry well.

In addition, drying guarantees a convenient and quick operation of the grinder, since the tool will not be clogged by wood fibers. You can replace this unit with a planer, in which case the above problems with wood processing will not arise.

Important! If the boards are not completely dried, their subsequent grinding will be unsuccessful.

Table parts manufacturing

Making a table for the gazebo is best to start with the processing of countertops. After it is ready, you can begin to study the legs and mounts for them. If you start work in the reverse order, there may be problems with the proportions of the finished product. Too large massive legs will be inconvenient to mount, and too elegant may not support the weight of the countertop.

Countertop

It is best for the countertop to prepare five boards of the same length and width. These plates are interconnected by four rails (50 × 50 mm). In the future, the legs of the table will be attached to these details. From the edge of the rail to the edge of the table should be at least 25 cm. In the future, the countertop will be sanded from all sides.

Legs

Having cut the boards in advance, it is necessary to start manufacturing. Two boards are inserted into the slats attached to the tabletop at a distance of 5 cm from each other. Then 4 rectangular pieces are cut out, after which their sides are cut at a slope of 40 °. These segments are attached at the bottom of the legs parallel to each other. Thus it turns out to create a platform on which the table will stand. After the parts are fastened, it is necessary to carefully grind them so that the piece of furniture is stable.

Benches

For each bench, based on the size of the table, it is necessary to cut the same wide boards, and then carefully grind them. For legs, both wood and metal pipe are suitable. Most often, the first option is used for gazebos. The shape of the mount may be different.

Important! The more even and clean the wood is selected, the less processing will be required in the future, and, as a result, the working time is also reduced.

It’s best to do the same as with the table:

- cut two slats and attach them across two boards prepared for the bench;

- then grind the legs and insert them between the rails with subsequent fastening.

Coating and Design

It is better to cover the finished product with a special varnish - this way the wood will not get wet and will last much longer. The simplest option is to paint tabletops with paints. This is done before the furniture is coated with a top coat of varnish, otherwise the paint will simply be erased. Another design option is mosaic layout. This option is easy to implement in the suburban area. You can decorate with glass, fragments of tiles or even dried flowers and leaves.

Features of the manufacture of metal tables

A metal product can be an excellent option for a summer cottage. The main obstacle to the implementation of the plan is that special equipment and welding skills are necessary to work with this material, otherwise you will have to ask for help from professionals. For beginners, it is easiest to give a large metal sheet a rounded or square shape that will serve as a worktop. Then attach a pipe or several pipe segments in a certain order perpendicularly to the center - these will be the supports.

Video: table made of wood and metal

You can combine iron parts with wood, for example, make a wooden tabletop and attach metal legs to it. Such a product will look more impressive. Based on the foregoing, we can conclude that with a great desire and certain skills, you can make a table with your own hands. The main thing is to pay special attention to the measurement and selection of material. Given the advice of experienced craftsmen and following the step-by-step manufacturing instructions, you can create a unique and stylish interior item.